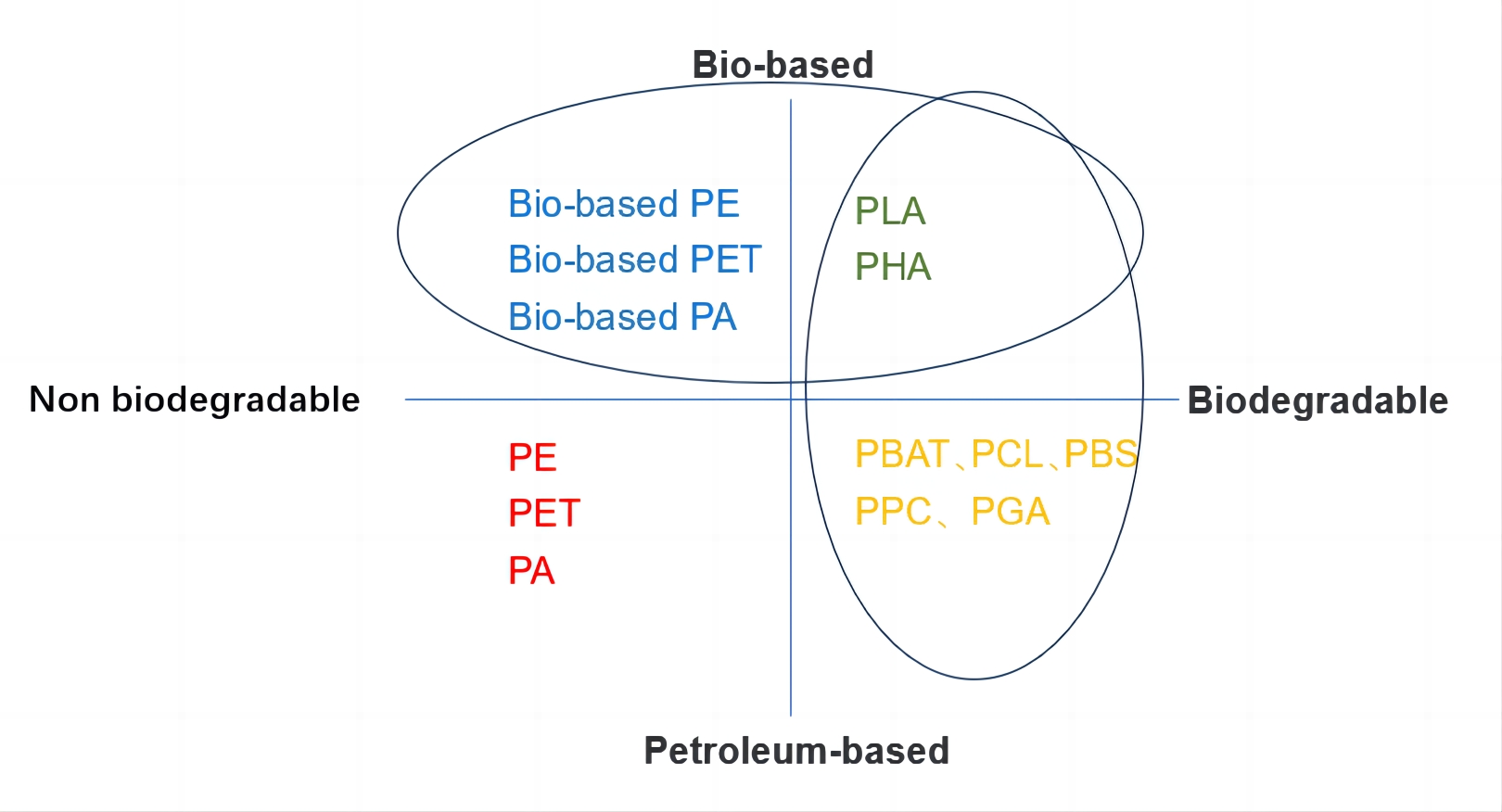

Low-density polyethylene (LDPE) is so far the most commonly used traditional barrier coating material for paperboard. Polylactic acid (PLA) is second to it, accounting more than 5% of the market share in the industry, which is quite an improvement versus 5 years ago. However, recent study and investigation into bioplastics has set off soul-searching over the promotion spree of PLA and polybutylene adipate terephthalate (PBAT). New findings have also impacted on its application in disposable tableware.

On June 29th 2023, the Environmental Protection Administration (EPA) in Taiwan, announced a ban on the use of tableware made from PLA, at eateries, retail stores and public-run institutions that came into effect on Aug 1st, 2023.

In the meanwhile, development of new bio-based material thrives. Take PHA as an example. Nowadays, it has fought its ways into manufacturing stage though years’ of concept study and laboratory tests. Last year, the first project of Bluepha™️ in Yancheng of Jiangsu has launched into production with an annual output of 5,000 tonnes. It is noteworthy that its second and third projects are already on the way with a capacity scale of tens of thousands tons for marine degradable biopolymer.

Driven by the demand from paperboard customers, the need to develop waterborne coatings as degradable barrier has come to the forefront. Paper and board are characterized as degradable packaging materials. Dispersion barrier coatings as solutions to reduce its reliance on plastic layers for barrier properties are highly competitive and promising. However, a sustainable future of the value chain will require further investment and research by the industry for product innovation and upgrading.

Post time: Apr-19-2024