Transfer Metallized Paperboard

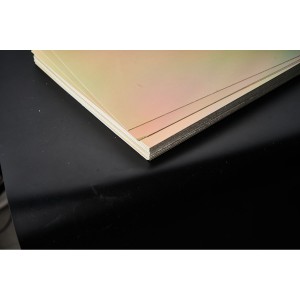

Product Structure

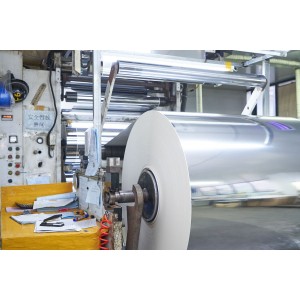

In the transfer metallization process, an extremely thin layer of aluminum is vacuum deposited onto a film and then adhesive-laminated to the paperboard. After a cure cycle the carrier film is removed, leaving a print-primed, glossy, silver or holographic surface on the board. Unlike conventional aluminum foil and film laminates, which relies on plastic films, transfer metallized board offers a more eco-friendly alternative. Designed and developed for sustainability without sacrificing performance in packaging, it is environmentally responsible and can help reduce your carbon footprint.

It is an environmentally friendly alternative to conventional aluminum foil and polyester film laminates.

It allows less aluminium to be used without compromising packaging performance.

The absence of plastic film enables the board to be completely plastic-free, allowing the board to be fully recyclable, biodegradable, compostable, and therefore reduce impact on environment.

Our transfer metallized paperboard clearly outperforms the competition for being easy to recycle and highly resistant to solvent. It beats competing grades in print results, and can be used with different printing techniques such as gravure, silk-screen, offset, flexo and UV.

It distinguished by its beautiful visual appearance and outstanding reliability. Boasting high brightness, it is resistant to rubbing, oxygen and moisture, aging and darkening.

Beating the solvent-based grades by excellent flexibility and tear resistance, it offers you the best print result and reduces the risks of ink cracking.

Printability

Suit for offset, UV printing, hot stamping, etc

Main End-uses

Packaging of cigarette, alcohol, food, cosmetics and any other packaging application that has a plastic-free requiremen

Technical Data Sheet

| Property | Tolerance | Unit | Standards | Value | |||||||

| Grammage | ±3.0% | g/㎡ | ISO 536 | 197 | 217 | 232 | 257 | 270 | 307 | 357 | |

| Thickness | ±15 | um | 1SO 534 | 245 | 275 | 310 | 335 | 375 | 420 | 485 | |

| Stiffness Taber15° | CD | ≥ | mN.3 | ISO 2493 | 1.4 | 1.5 | 2.8 | 3.4 | 5 | 6.3 | 9 |

| MD | ≥ | mN.3 | 2.2 | 2.5 | 4.4 | 6 | 8.5 | 10.2 | 14.4 | ||

| Surface tension | ≥ | dyn/cm | -- | 38 | |||||||

| Brightness R457 | ≥ | % | ISO 2470 | Top:90.0 ;Back:85.0 | |||||||

| PPS (10kg.H)top | ≤ | um | ISO8791-4 | 1 | |||||||

| Moisture (at Arrival) | ±1.5 | % | 1S0 287 | 7.5 | |||||||

| IGT Blister | ≥ | m/s | ISO 3783 | 1.2 | |||||||

| Scott Bond | ≥ | J/㎡ | TAPPIT569 | 130 | |||||||